|

|

|

|

|

|

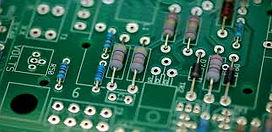

Components with wire leads are generally used on through-hole boards. Axial leads protrude from each end of a typically cylindrical or elongated box-shaped component, on the geometrical axis of symmetry.

Axial-leaded components resemble wire jumpers in shape, and can be used to span short distances on a board, or even otherwise unsupported through an open space in point-to-point wiring.

Axial components do not protrude much above the surface of a board, producing a low-profile or flat configuration when placed "lying down" or parallel to the board.

Radial leads project more or less in parallel from the same surface or aspect of a component package, rather than from opposite ends of the package. Originally, radial leads were defined as more-or-less following a radius of a cylindrical component (such as a ceramic disk capacitor). Over time, this definition was generalized in contrast to axial leads, and took on its current form.

When placed on a board, radial components "stand up" perpendicular, occupying a smaller footprint on sometimes-scarce "board real estate", making them useful in many high-density designs. The parallel leads projecting from a single mounting surface gives radial components an overall "plugin-nature", facilitating their use in high-speed automated component insertion ("board-stuffing") machines.

When needed, an axial component can be effectively converted into a radial component, by bending one of its leads into a "U" shape so that it ends up close to and parallel with the other lead. Extra insulation with heat-shrink tubing may be used to prevent shorting out on nearby components.

Conversely, a radial component can be pressed into service as an axial component by separating its leads as far as possible, and extending them into an overall length-spanning shape. These improvisations are often seen in breadboard or prototype construction, but are deprecated for mass production designs. This is because of difficulties in use with automated component placement machinery, and poorer reliability because of reduced vibration and mechanical shock resistance in the completed assembly.

SA Electronics performs leaded or lead-free (RoHS) through-hole and mixed assembly for simple and high complexity circuit boards.

|

|

|

|

|

|

Through Hole

Axial- (top) and radial- (bottom)